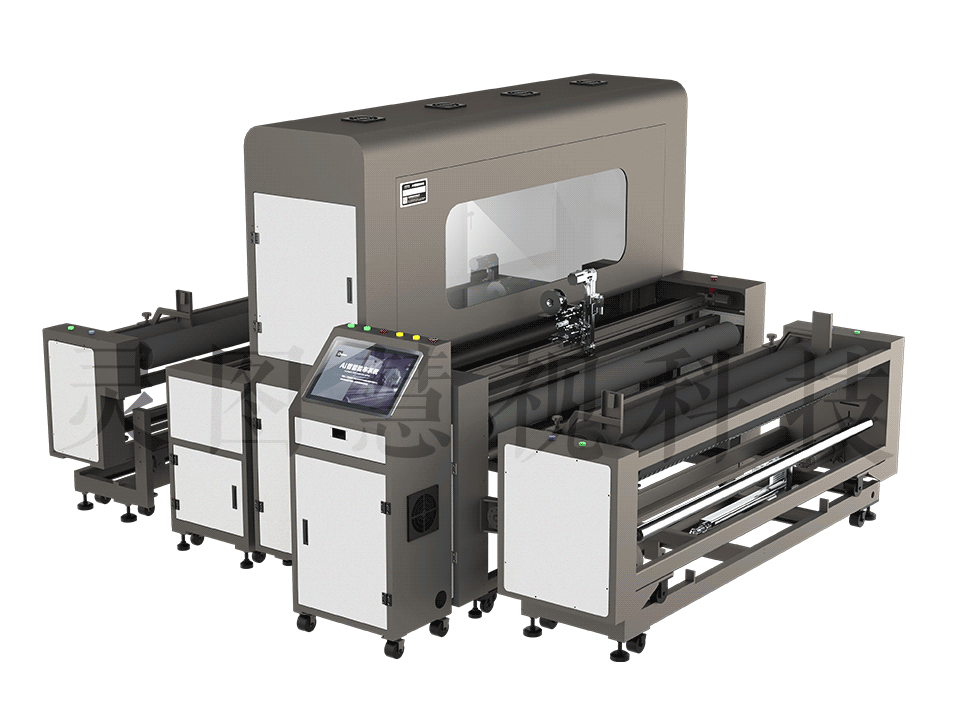

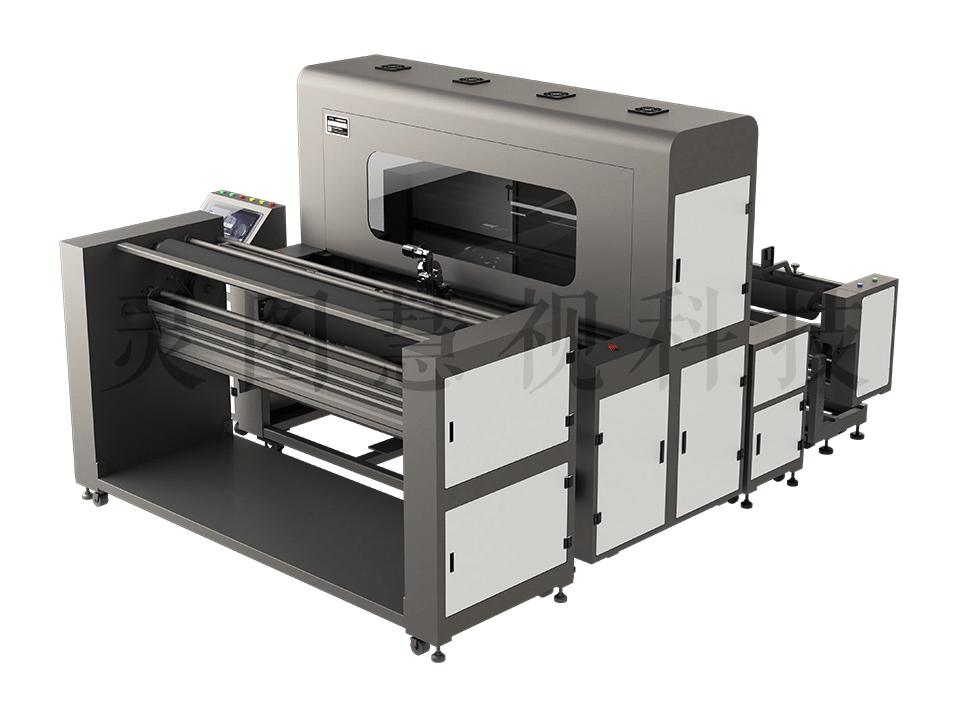

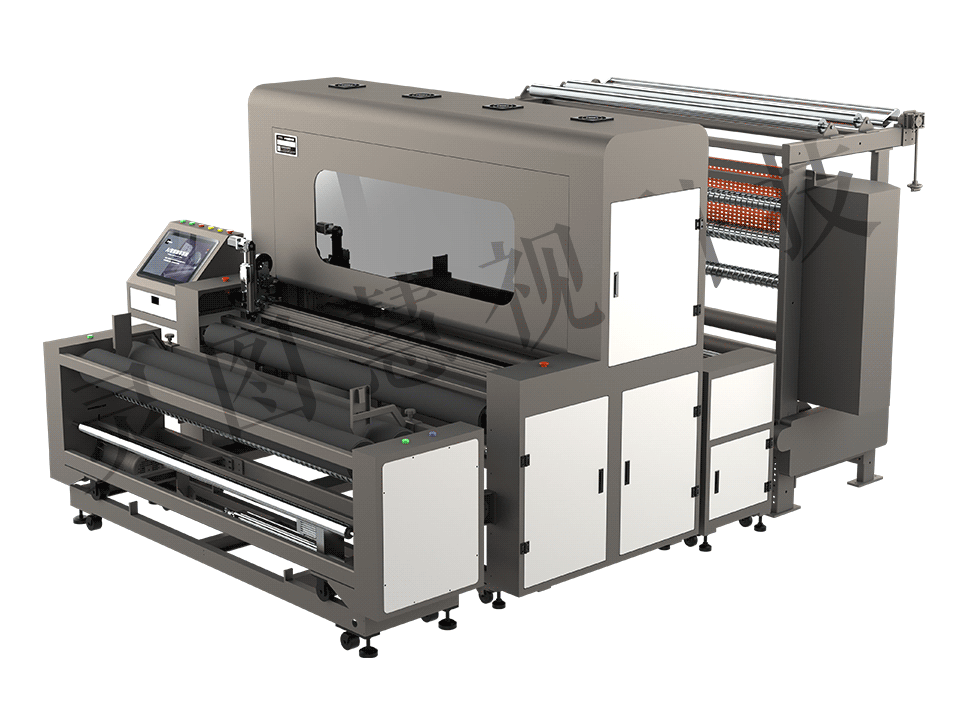

AI Fabric Inspecting Robot

01The software uses artificial intelligence technology - deep convolutional neural network combined with image recognition technology to detect, classify and automatly updating the learning of fabric defects. And the multifuntional hardware provides defects marking, length recording and fabric folding all on one AI fabric inspecting robot.